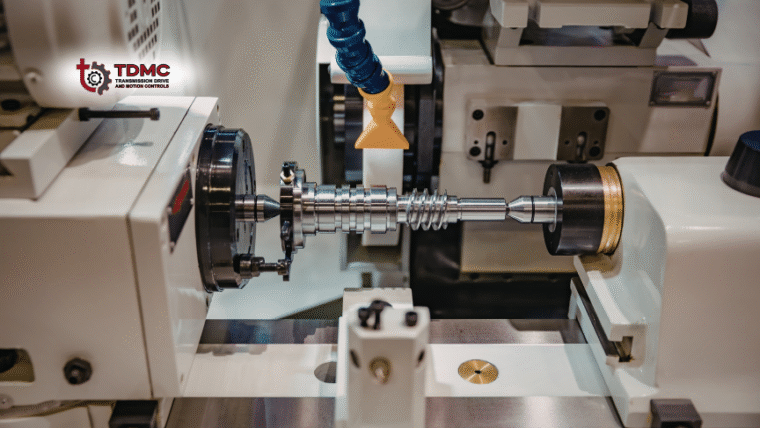

When it comes to ensuring smooth operation and durability in machinery, selecting the right Parallel Shafts is crucial. These components play a vital role in power transmission, aligning multiple rotating parts, and maintaining mechanical efficiency. But with so many options available, how do you choose the best parallel shafts for your specific machinery needs? Let’s dive into some key factors to consider.

- Material and Strength

One of the first considerations is the material from which the parallel shafts are made. Common materials include carbon steel, stainless steel, and alloy steel. The choice depends on the working environment and load requirements:

- Load Capacity: Make sure the shaft material can handle the maximum torque and stress it will encounter.

- Corrosion Resistance: If your machinery operates in harsh or humid conditions, corrosion-resistant materials like stainless steel are preferable.

- Wear Resistance: High-quality materials reduce wear and extend the shaft’s lifespan.

- Precision and Tolerance

These need to maintain exact alignment to avoid vibrations and premature wear in machinery. Precision manufacturing ensures shafts fit perfectly with bearings, gears, and couplings. Look for shafts with:

- Tight dimensional tolerances

- Smooth surface finishes

- Balanced construction to reduce noise and vibration

- Size and Dimensions

Choosing the right size of shafts is vital for optimal performance:

- Diameter and Length: Should be based on the machine design and load requirements.

- Shaft Keyways or Splines: These features affect how torque is transmitted and must match other components precisely.

- Weight Considerations: Heavier shafts may increase the load on bearings and affect machine efficiency.

- Compatibility with Machinery Components

Your parallel shafts must be compatible with the other mechanical parts in your setup:

- Ensure proper fit with bearings and couplings.

- Check that the shaft’s design aligns with gear assemblies or pulleys.

- Confirm the shaft can be easily installed and maintained within your machinery.

- Cost and Availability

While quality should never be compromised, budget and lead times also matter. Some high-performance shafts might be costlier but can save money over time with less downtime and fewer replacements.

Selecting the right Parallel Shafts is more than just picking a part off the shelf. Considering material, precision, size, compatibility, and cost will help you make an informed decision that enhances your machinery’s efficiency and longevity. Always consult with a trusted supplier or engineer to ensure you get the best fit for your needs.